Vigour

Vigour cardigan backside. Photo by Joe Hammond

Vigour cardigan backside. Photo by Joe HammondA knitted cardigan that keeps people active

Vigour is a Product Service System that enables geriatric patients, physiotherapists and family to gain more insight into the exercises and progress of a rehabilitation process. It is a knitted, long-sleeved cardigan with integrated stretch sensors made of conductive yarn and an accompanying iPad application which monitors the movements of the upper body and can give sound feedback. The garment can be worn all day and thereby gather a large amount of data.

Vigour introduction, video by Joe HammondSound as motivation

Next to this the garment can be worn when executing rehabilitation exercises and give feedback to the wearer by making sounds on an iPad application. For example: the further a particular sensor is stretched, the higher the pitch of the piano or the increase in volume of the voice in a song. Vigour’s accompanying iPad app uses this data to give direct feedback to both the sweater’s wearer and the physiotherapist, helping them both visualise progress. It also allows them to customise each sensor’s sound and sensitivity, providing another way to track effort in each targeted area. The project has a high social value, since it advances ways of communication between geriatric (Alzheimer’s) patients and their therapists, and encourages interaction and movement.

Sound feedback of Vigour, app by Lisa Vork, sound design by Silvin WillemsenVigour prototype

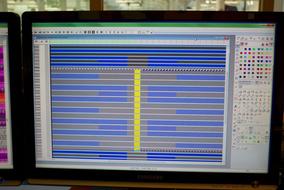

Vigour is designed in the form of a garment that can be worn as a normal cardigan. The reason for this is that the garment is more likely to be accepted by the target group (older adults and seniors). Family and caregivers do not like the stigma of a patient that a garment with a strong medical look puts on the wearer. It is important that the person wants to wear it, first of all because it is comfortable and also fits their identity and is beautiful, and additionally has the other features you expect from a smart garment. The sensor areas themselves are directly knitted into the fabric during the knitting process. There are in total four sensors integrated into the textile of the garment: two in the lower back area, to measure back movement (bend of the back), and two stretch sensors under the arms to measure arm movement.

Details

- Designers: Martijn ten Bhömer, Pauline van Dongen, Oscar Tomico

- Partners: De Wever, Metatronics, Unit040, Savo BV, TextielMuseum TextielLab

- Students: Annelie van Lankveld, Daisy van Loenhout, Lisa Vork & Silvin Willemsen

- Materials: Wool, Elastomeric Bemis adhesive, Conductive Bekinox yarns, Custom electronic CRISP PCB modules, Elastic Ohmatex cabling, 3D printed casings, Battery

- Techniques: Stoll knit & wear knitting, 3D printing, Overlocking, Sewing, Soldering, Laminating, Programming

- My role in collaboration: Initiator of the project, User-centered design and validation, Integration of textile and technology & Interaction design